When it comes to elevating your woodworking craftsmanship, choosing the right router motor slider can make all the difference. These precision tools enhance efficiency and accuracy, allowing you to tackle a variety of projects with ease. From powerful linear actuators to compact options, there’s a perfect fit for every woodworker. Curious about which sliders stand out in the market? Let’s explore the top choices that could transform your woodworking experience.

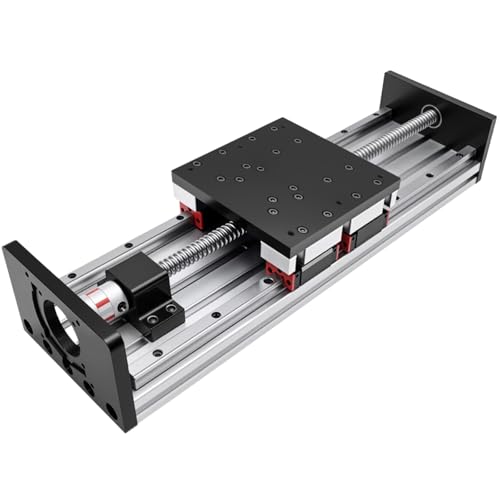

FUYU FPB45 CNC Linear Rail Slide Guide Motion Actuator

If you’re a woodworking enthusiast or a professional looking to enhance your CNC capabilities, the FUYU FPB45 CNC Linear Rail Slide Guide Motion Actuator stands out as an exceptional choice. With a maximum speed of 1400mm/s and a precision of 0.05mm, it guarantees accuracy in every task. You can customize the stroke and motor options to suit your specific needs. This actuator’s lightweight yet sturdy build allows seamless integration into various CNC and robotic systems, making it perfect for engraving and milling. Plus, its lubrication-free design keeps operations quiet, guaranteeing a smooth workflow even under heavy use.

Best For: Woodworking enthusiasts and professionals seeking to enhance their CNC capabilities with high-speed, precise motion control.

Pros:

- High-speed operation allows for faster project completion, up to 1400mm/s.

- Customizable options for stroke length and motor type cater to specific user needs.

- Lubrication-free design ensures low maintenance and quiet operation during use.

Cons:

- Maximum load capacity of 15KG may limit use with heavier materials or tools.

- Initial setup complexity may require technical knowledge for optimal integration.

- Customization requests for non-standard strokes may involve additional lead time.

UYGALAXY Mini Linear Rail Stage Actuator for DIY CNC Router Parts

The UYGALAXY Mini Linear Rail Stage Actuator is an ideal choice for DIY enthusiasts looking to enhance their CNC router projects, thanks to its compatibility with NEMA11 stepper motors. With a compact design featuring a 2-inch stroke length, this actuator supports a maximum horizontal load of 2.5 kg, making it robust yet efficient. It operates at 24VDC with speeds up to 10mm/s, ensuring precision with a screw accuracy of 0.1mm. Perfect for various applications, it offers high efficiency and a long operational life, helping you achieve fine-tuned displacement and precise positioning in your woodworking tasks.

Best For: DIY enthusiasts and hobbyists looking to improve their CNC router projects with a compact and efficient linear actuator.

Pros:

- High precision with a screw accuracy of 0.1mm, ensuring accurate positioning.

- Compact design with a 2-inch stroke length, ideal for limited spaces.

- Versatile applications, suitable for various tasks including mechanical positioning and optical measurements.

Cons:

- Requires additional drive and controller for stepper motor operation, which may increase setup complexity.

- Limited maximum load capacity (2.5kg horizontally and 1kg vertically) may not suit heavier applications.

- The actuator is designed for a specific motor type (NEMA11), limiting compatibility with other motors.

RATTMMOTOR CNC Linear Stage Motion Actuator

For woodworkers seeking precision and reliability, the RATTMMOTOR CNC Linear Stage Motion Actuator stands out with its 100mm effective stroke and robust load capacities of 120kg horizontally and 50kg vertically. This actuator features a cross sliding table with double linear slide rail guides, ensuring smooth operation. You’ll appreciate the SFU 1605 ballscrew, which guarantees accuracy up to 0.03mm. Crafted from high-quality aluminum alloy, it’s durable, rust-resistant, and wear-resistant. The package includes limit switches and a motor mount bracket, making setup straightforward. With its high-speed, silent operation, this actuator enhances your woodworking experience considerably.

Best For: Woodworkers and CNC enthusiasts seeking a precise and reliable linear motion actuator for their projects.

Pros:

- High Load Capacity: Can support up to 120kg horizontally and 50kg vertically, making it suitable for a variety of applications.

- Precision Engineering: The SFU 1605 ballscrew offers an accuracy of up to 0.03mm, ensuring high precision in movements.

- Durable Construction: Made from high-quality aluminum alloy, ensuring longevity and resistance to rust and wear.

Cons:

- Motor Not Included: Requires a separate motor purchase, which can increase overall costs.

- Limited Stroke Length: The effective stroke of 100mm may not be sufficient for larger projects.

- Complex Setup for Beginners: May require technical know-how for installation and calibration, which could be challenging for novice users.

Linear Rail Linear Stage Actuator with NEMA 11 Stepper Motor

Crafted for precision and versatility, the Linear Rail Linear Stage Actuator with a NEMA 11 stepper motor is an ideal choice for woodworking enthusiasts and professionals alike. With travel lengths of 50mm, 100mm, 150mm, and 200mm, it features a compact 100mm travel length and a mini slide table. This actuator supports a maximum load of 3 KG and a vertical load of 1 KG, making it reliable for various projects. Constructed from high-quality aluminum alloy and stainless steel, it guarantees durability. Its versatility and precision are enhanced by customizable screw specifications, allowing you to tailor it to your specific needs.

Best For: This product is best for woodworking enthusiasts and professionals seeking a compact and precise actuator for their CNC projects.

Pros:

- High precision and efficiency, ensuring accurate movements for various applications.

- Durable construction from high-quality aluminum alloy and stainless steel for long-lasting use.

- Customizable screw specifications to meet specific project requirements.

Cons:

- Limited maximum load capacity of 3 KG, which may not be suitable for heavier applications.

- Vertical load limit of 1 KG may restrict its use in certain vertical setups.

- The compact travel length of 100mm may not be adequate for larger projects requiring more extensive movement.

BORA 3.25HP Soft Start Router Motor with Variable Speed PM-6200

With its powerful 3.25HP motor and soft start feature, the BORA 3.25HP Soft Start Router Motor PM-6200 is perfect for woodworkers seeking reliability and precision. You’ll appreciate the variable RPM range of 10,000 to 22,000, allowing you to maintain consistent speed even under varying loads. Its two precision ER20 collets (1/4 inch and 1/2 inch) guarantee compatibility with standard bits, enhancing your routing accuracy. Plus, the motor’s 4.2-inch diameter fits most router lifts and tables, making it a versatile choice for both home and professional setups. Elevate your woodworking projects with this robust and adjustable router motor.

Best For: Woodworkers and CNC operators seeking a reliable and precise router motor for their projects.

Pros:

- High-powered 3.25HP motor with a soft start feature to prevent startup surges.

- Variable RPM range of 10,000 to 22,000 with electronic speed control for consistent performance.

- Includes two precision ER20 collets for compatibility with standard routing bits.

Cons:

- The motor’s 4.2-inch diameter may not fit all router lifts and tables.

- The fixed router base (BORA PM-6210) is sold separately, adding to the overall cost.

- As a high-power tool, it may require a dedicated circuit for optimal performance.

28 Stepper Motor Mini Linear Rail Slide Actuator

The 28 Stepper Motor Mini Linear Rail Slide Actuator is a fantastic choice for woodworking enthusiasts looking to enhance their DIY CNC projects. With an effective travel and stroke of 50mm, this actuator offers great precision for your applications. Its low noise monorail design guarantees stable operation across X, Y, and Z axes. You’ll appreciate its large load capacity and high positioning accuracy, making it ideal for CNC milling machines and mechanical positioning tasks. Constructed from durable alloy with a thickened bottom plate, this actuator ensures stability and reliability, guaranteeing your projects run smoothly every time.

Best For: DIY CNC enthusiasts seeking a reliable and precise actuator for their woodworking projects.

Pros:

- High positioning accuracy ensures precision in CNC applications.

- Durable construction with a thickened bottom plate offers stability and longevity.

- Low noise operation allows for a quieter working environment.

Cons:

- Limited travel distance of 50mm may not be sufficient for larger projects.

- Stepper motor may require additional components for optimal performance in complex setups.

- Initial setup may be challenging for beginners without prior experience in CNC machinery.

Heavy Duty Linear Stage Motion Actuator for CNC Router

For woodworkers seeking precision and power, the Heavy Duty Linear Stage Motion Actuator for CNC routers stands out with its impressive load capacity of 550 lb (250 kg). Featuring a 2005 ballscrew with a diameter of 20 mm, it delivers an accuracy of ±0.02 mm, ensuring your cuts are always precise. With a mobile panel size of 5.9 x 6.7 inches, it operates smoothly at speeds up to 4 inches per second. Its aluminum structure guarantees strength and rust resistance, making it perfect for demanding applications. This actuator enhances your CNC router’s performance, meeting the needs of any serious woodworking project.

Best For: This product is best for professional woodworkers and manufacturers requiring high precision and heavy load capabilities in their CNC routing operations.

Pros:

- High load capacity of 550 lb (250 kg) allows for versatile applications in demanding environments.

- Precision accuracy of ±0.02 mm ensures detailed and exact cuts, enhancing overall project quality.

- Durable aluminum construction provides rust resistance and longevity, suitable for industrial use.

Cons:

- Motor not included, requiring additional purchase which may increase total setup costs.

- Max speed of 4 inch/s may not meet the needs of those requiring faster operation for large-scale projects.

- Limited vertical load capacity of 220 lb (100 kg) might restrict usage in certain applications compared to other models.

RATTMMOTOR EBX1605 CNC Linear Stage Actuator

Designed for precision and stability, the RATTMMOTOR EBX1605 CNC Linear Stage Actuator is an ideal choice for DIY enthusiasts and professionals looking to enhance their woodworking projects. With a working length of 300mm and a robust Nema23 stepper motor, you’ll enjoy reliable performance. Its compact aluminum structure and double optical axis guarantee stability, while the 1605 ball screw delivers outstanding accuracy, achieving a screw reciprocating accuracy of 0.01mm. Plus, its flexible installation options allow for various configurations. Supporting loads up to 50KG horizontally, this actuator is perfect for CNC routers, lathes, and industrial automation devices.

Best For: DIY enthusiasts and professionals looking for a reliable and precise CNC linear actuator for woodworking and industrial automation projects.

Pros:

- High precision: Achieves screw reciprocating accuracy of 0.01mm for exceptional accuracy in operations.

- Robust load capacity: Supports up to 50KG horizontally and 10KG vertically, making it suitable for various applications.

- Flexible installation: Offers multiple configuration options for diverse setups, including multi-axis systems.

Cons:

- Limited working length: The 300mm length may not be sufficient for larger projects that require extended travel.

- Requires expertise: Installation and setup may require some technical knowledge for optimal performance.

- Stepper motor limitations: While effective, stepper motors can be less efficient at higher speeds compared to other motor types.

UYGALAXY Mini Linear Rail Stage Actuator with NEMA11 Motor

Engineered for precision and efficiency, the UYGALAXY Mini Linear Rail Stage Actuator with NEMA11 Motor is an excellent choice for DIY enthusiasts and professional woodworkers alike. With a 10-inch stroke length and a load capacity of 2.5 kg horizontally, it offers versatility for various applications, from CNC routers to fine-tuning equipment. The actuator operates at speeds up to 10 mm/s, ensuring swift movements while maintaining high precision. Its low friction design promotes longevity, making it a reliable addition to your toolkit. Plus, it comes with a user manual to help you get started right away.

Best For: DIY enthusiasts and professional woodworkers looking for a precise and efficient linear actuator for various applications.

Pros:

- High precision ensures accurate movements for intricate projects.

- Versatile applications make it suitable for CNC routers, inspection equipment, and more.

- Low friction design promotes longevity and reliability in operation.

Cons:

- Limited load capacity may not be suitable for heavier applications.

- Speed range is capped at 10 mm/s, which might be slow for some users.

- Requires 24VDC power supply, which may necessitate additional equipment for some users.

HGR20 Linear Rail and RM1605 Ballscrew Set for DIY CNC Routers

When precision is essential in your woodworking projects, the HGR20 Linear Rail and RM1605 Ballscrew Set stands out as an exceptional choice for DIY CNC routers. Made from high-quality carbon steel, this set features chrome plating for anti-rust protection and remarkable hardness. Its easy installation process, with pre-drilled holes and stainless steel bearings, guarantees smooth linear movement. The motor-driven guide rail offers high precision with low friction, while the ball screw minimizes torsion for accurate positioning. Whether you’re building a CNC router or other automation machinery, this set is perfect for achieving reliable, precise linear motion in your projects.

Best For: DIY enthusiasts and professionals looking for high-precision components for CNC routers and automation machinery.

Pros:

- High durability: Made from carbon steel with chrome plating for enhanced anti-rust protection and exceptional hardness.

- Easy installation: Features pre-drilled holes and stainless steel bearings for straightforward mounting and smooth operation.

- Precision performance: Motor-driven guide rail and ball screw design ensure low friction and accurate positioning for reliable linear motion.

Cons:

- Limited to specific applications: Best suited for CNC routers and similar machinery, may not be ideal for other types of projects.

- Potential weight: The robust construction may add extra weight, which could be a consideration for portable setups.

- Requires additional components: While the set includes essential parts, users may need to purchase additional components for complete assembly.

Factors to Consider When Choosing Router Motor Sliders

When you’re choosing router motor sliders, you’ll want to think about several key factors. Load capacity, precision, and motor compatibility can greatly influence your setup’s performance. Additionally, stroke length and build material quality are essential for ensuring durability and effectiveness in your woodworking projects.

Load Capacity Considerations

Choosing the right router motor slider involves careful consideration of its load capacity, as this directly impacts both performance and safety. You’ll want to check both horizontal and vertical load capacities, which can greatly differ. For example, some sliders support horizontal loads up to 120 kg and vertical loads of 50 kg. Make sure the load capacity aligns with the weights of your materials and tools; exceeding this can damage your equipment. Also, consider the effective stroke length—shorter strokes may have lower capacities. Additionally, evaluate the materials used; higher-quality aluminum or steel typically provides better load-bearing capabilities and durability, ensuring your slider can handle the demands of your woodworking projects effectively.

Precision and Accuracy

Load capacity is just one aspect to contemplate; precision and accuracy play a crucial role in the performance of router motor sliders. High-end models can offer precision levels as fine as ±0.01mm to ±0.05mm, ensuring your cuts are exact. Look for sliders with advanced screw mechanisms, like ballscrews graded C7, which enhance accuracy and reduce friction. Speed also matters; some linear stages can reach up to 1400mm/s, impacting efficiency and precision in your movements. Finally, consider features like limit switches and encoders, which greatly improve positioning precision and repeatability. By focusing on these factors, you can choose a router motor slider that elevates your woodworking projects to a new level of craftsmanship.

Motor Compatibility Options

Selecting the right router motor slider involves understanding motor compatibility options that best fit your specific setup. First, verify the slider supports your stepper motor type, like NEMA 11 or NEMA 23, as these are common in various applications. Next, check the voltage and current ratings; some sliders might need a 24VDC supply with a current of 0.5A. It’s also important to take into account the load capacity of the slider, especially if you’re handling heavier tasks—look for models that can support at least 15KG. Finally, explore sliders offering customizable screw specifications to enhance performance and tailor the setup to your project needs. Making these considerations will lead to a more efficient and satisfying woodworking experience.

Stroke Length Requirements

When it comes to router motor sliders, understanding stroke length requirements is essential for effective woodworking. The stroke length determines how far the slider can travel, significant for accommodating your workpieces. If you need precise positioning, choose a stroke length that exceeds your maximum travel requirements to allow flexibility and avoid operational limits. Stroke lengths typically range from 50mm to 3500mm, so select based on your project needs. While longer strokes enable more complex tasks, they may require additional space and careful consideration for mounting. Also, keep in mind the relationship between stroke length and load capacity, as longer strokes can impact stability and accuracy when handling heavier loads. Selecting the right stroke length is key to optimizing your woodworking projects.

Build Material Quality

While you might be tempted to focus solely on features, the build material quality of router motor sliders plays an important role in their performance and longevity. High-quality materials like aluminum alloys and stainless steel enhance durability and rust resistance. Using carbon steel and chrome plating in linear rails guarantees superior hardness and protection against rust, boosting the lifespan of your slider. The materials you choose also affect weight and rigidity; lighter constructions allow for easier movement while maintaining structural integrity under load. Precision components, such as high-grade bearings, are vital for smooth operation and accuracy, minimizing friction and wear. Investing in robust construction helps prevent deformation, guaranteeing consistent performance across various applications.

Noise Level Assessment

High-quality build materials contribute to the overall performance of router motor sliders, but noise levels also play a crucial role in your woodworking experience. If you’re working in a quiet workshop or residential area, consider sliders that operate at lower noise levels. Look for linear stage actuators with lubrication-free components, as they promote smoother, quieter motion. Products featuring high-quality bearings and sliders are engineered to minimize vibrations, creating a more pleasant work environment. Additionally, designs incorporating dustproof profiles and damping materials can greatly reduce operational noise. Consistent, low noise levels not only enhance comfort but often indicate better efficiency and precision, with quieter systems typically translating to smoother functionality and decreased wear over time.

Application Versatility

How do you guarantee your router motor slider meets the demands of various woodworking tasks? Start by considering application versatility. Look for sliders that can handle multiple functions, like CNC engraving, milling, and material handling, all while maintaining precision. Aim for models with an effective stroke length and a load capacity of at least 550 lb (250 kg) for heavy-duty projects. Precision is key; choose sliders that offer accuracies of 0.01mm or better for high-precision work. Additionally, low noise operation is vital for long-running tasks, keeping your workspace efficient and peaceful. Finally, versatile designs that support various motor types and custom stroke lengths will assure your slider adapts easily to different DIY and industrial automation projects.

Maintenance and Durability

When choosing a router motor slider, it’s crucial to prioritize maintenance and durability to guarantee long-lasting performance. Opt for robust materials like high-quality aluminum alloy or carbon steel, as these enhance durability and resist wear and rust. A lubrication-free design in linear actuators reduces the need for regular maintenance, allowing for hassle-free operation. Look for features like dustproof profiles and low noise operation, which help protect internal components and create a cleaner workspace. Additionally, choose sliders with high-quality bearings and precision screws, preferably C7 grade or better, to promote smooth movement and minimize friction. Finally, regularly inspect critical components like linear rails and screws to prevent failures and extend your slider’s lifespan.

![FUYU FPB45 CNC Linear Rail Slide Guide Belt Drive Linear Stage Motion Actuator Router Parts Motorized Nema Stepper Servo Motor[1500mm Work Size Stroke]](https://m.media-amazon.com/images/I/31Mk+-L+O3L._SL500_.jpg)